E - 01 - STEAM DEAERATOR

Taravosh Jam is a Manufacturer in Iran & Middle east for design and delivery of the Steam Deaerator. Deaerator (thermal or pressurized) is a Degasification device

E – 01 – STEAM DEAERATOR

Taravosh Jam is a Manufacturer in Iran & Middle east for design and delivery of the Steam Deaerator. Deaerator (thermal or pressurized) is a Degasification device

Deaerator is an equipment that is used to remove oxygen and dissolved gases like carbon dioxide in the boiler feed water. Oxygen & carbon dioxide is the primary cause of corrosion of units. Oxygen dissolved in water, causing severe damage caused by corrosion in steam boilers. Carbon dioxide is acidic water. This type of corrosion is usually Pitting corrosion.

The Deaerator capacity is the boiler capacity plus the amount of continuous Blow Down of the boiler.

Boiler Operator is minimized flow of continuous Blow Down of the boiler to save fuel consumption. In Deaerator capacity is assumed the maximum continuous Blow Down of the boiler. Deaerator capacity is taken to be critical operation times (such as the worst purity on the water or oily water).

If the water is at its saturation temperature of the gas dissolution rate is almost zero. Therefore water must be high turbulence or should boil to ensure complete removal of all the gas.

remove the oxygen by 7ppb

the elimination of carbon dioxide

prevent corrosion and thermal stress boiler

improve thermal efficiency

providing feed water pump NPSH

water storage for 5 to 20 minutes for the boiler (holding time)

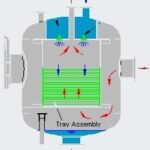

Steam contact with boiler feed water causes heat to rise and reduce the solubility of oxygen in the water .Spray Deaerator creates a fine water droplet that provides the best transfer of mass and heat. It performs 90% Deaeration. The Deaerator trays increase the mass transfer and reduce the outlet vent steam. In Steam injection-Type Deaerator, the steam is injected under the surface of the water, which is an old method and cheap. In this model, corrosion is increase in storage tank.

It is recommended that the condensate return be sent directly to the Deaerator. Cooling down the condensate return is energy waste. The Deaerator storage tank is easy to separate steam and water of condensate return.

The steam consumption Deaerator is usually one-sixth of the Deaerator capacity.