P – 08 - INDUSTRIAL & OILY WATER TREATMENT PACKAGES

Taravosh Jam Co. is a Manufacturer in Iran & Middle east for design and delivery of the Industrial &oily water treatment packages as following

P – 08 – INDUSTRIAL & OILY WATER TREATMENT PACKAGES

Taravosh Jam Co. is a Manufacturer in Iran & Middle east for design and delivery of the Industrial &oily water treatment packages as following

The evaporation process is the only way to separate oil from water without having to pre-treat the effluent or requiring subsequent processes, as the water produced is of higher quality and can be reused directly.

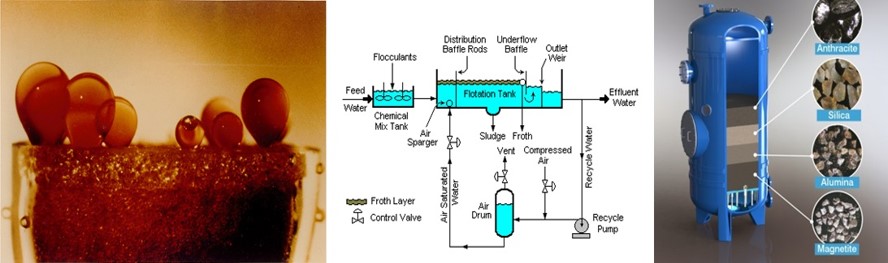

DAF is designed to remove suspended solids (TSS), biochemical oxygen demand (BOD5), and oils and greases (O&G) from a wastewater stream. Injecting air into a recycle stream causes that the bubbles and contaminants rise to the surface and form a floating bed of material that is removed by a surface skimmer. The reduction of oil up to 10 ppm is anticipated.

reduce the level of suspended solids (small particles such as silt, clay, grit, organic matter, algae, and other microorganisms) in incoming feed water to 5-2 microns. Multimedia Filter protects downstream filtration equipment such as reverse osmosis membranes and ion exchange beds.

is a vertical up-flow pressure filter. The de-oiling process consists in filtering the oily water stream through two separate coalescing zones around one ppm concentration.

In the primary coalescing zone, the separation of the free oil droplets from the water stream occurs on the surface of the resin beads, where a thin oil film is formed during the process, due to the unique characteristics of the resin material.

When the oil film thickness increases, the coalesced oil migrates upward within the resin layer. As a consequence, the upper layer of the resin bed is always almost saturated with oil, so that it releases the coalesced oil in the form of larger droplets that move upward, towards the secondary coalescing zone.

issued to remove suspended solids concentration, oil and grease hydrogen sulfide, chlorine, and pesticides contents down to < 0.5 mg/l for inlet the 1-10 mg/l range.

issued to remove suspended solids from liquids water. Centrifugal forces separate particles with a higher density than the liquid, and they fall to the separator vessel.

Units separate and recover oil and fine solid particles from water through the creation of fine gas bubbles (typically < 50 microns in diameter) that are dispersed through the incoming water stream.

MAX. Removal of oil down to <15 ppm, >90% oil removal

MAX. Removal of fine solids (<10 microns), >80% removal of fine

are used as water treatment devices and installed downstream Induced Gas Flotation (IGF). Nutshell filters use a fluidized media cleaning process that effectively strips contaminants and oil from the media with very little backwash water and no surfactants or gas/air scour.

95% removal efficiency particulate solids <3 ppm down to 5 microns in size

95% removal efficiency oil <3 ppm